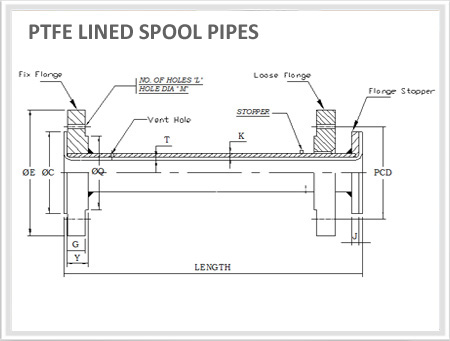

PTFE LINED SPOOL PIPES

- Product Name: PTFE LINED SPOOL PIPES

- Product Code : Spool

- Product Display Name : Lined spool

- Faab Industries offering the complete range which includes PTFE Lined Pipes, MS PTFE Lined Pipes, PTFE Lined pipes Manufacturers, PTFE Lined Pipe Price List, PTFE Lined Products, PTFE Lined Pipe full form, PTFE Lined Pipe Manufacturers India, PTFE Lined Pipe Specification, SS & MS PTFE Lined Pipes for Saudi Arabia, Kuwait, UAE, Qatar, Oman, Egypt, Turkey, Iran, USA, Canada, Mexico. Faab Industries is one of the Leading Manufacturer & Exporter of High-Quality PTFE Lined Pipes from india. Export & Supply in Saudi Arabia, Kuwait, UAE, Qatar, Oman, Egypt, Turkey, Iran, USA, Canada, Mexico. We are One of The Reputed Manufacturer, Supplier & Exporter of PTFE Lined Pipes from india. Export & Supply in Saudi Arabia, Kuwait, UAE, Qatar, Oman, Egypt, Turkey, Iran, USA, Canada, Mexico. ISO Certified. Superior Quality Products. Long Life. Global Supply. Assured Quality. Fast Delivery.

Description:

SIZE RANGE: 1” – 24”

MATERIAL OF CONSTRUCTION: Lined pipes are manufactured using Carbon Steel pipe material as per ASTM A106 Gr. B, seamless as per schedule 40 for lining spools of 1” to 8” size, sch 30 for 10" to 12" and sch 20 for 14" to 24".

Material Test Certificates (MTC) can be supplied along with heat numbers on demands.

Flange material is as per A105 forged flanges/ IS 2062 Gr. B and dimensions are as per ANSI B 16.5 ASA 150#.

Straight spools of lined pipe can be offered for maximum length of 6000 mm (6 mtr) upto 8" and 3000 mm (3 mtr) for 10" - 16" sizes.

LINING MATERIAL: PTFE (POLY TETRAFLUORO ETHYLENE) / PP (POLY PROPELENE) / HDPE (HIGH DENSITY POLYETHYLENE)

Short Description: CS – PTFE / PP / HDPE LINED PIPE SPOOL

Features & Specifications: PAINTING RED OXIDE PRIMER

Dimensional details are as per below table

| SIZE | Min. Avail Length with flange | Max. Length Avail. | Flange Stopper Thik "J" | Wgt per mtr length | Wgt + ~ 1 mtr |

|

| NB | INCH | (mm) | (mm) | (mm) | (Kg) | (Kg) |

| 25 | 1" | 100 | 6000 | 10 | 5.5 | 3.3 |

| 40 | 1.5" | 100 | 6000 | 10 | 8.5 | 5.5 |

| 50 | 2" | 100 | 6000 | 10 | 11.0 | 6.5 |

| 80 | 3" | 110 | 6000 | 10 | 20.0 | 13.0 |

| 100 | 4" | 110 | 6000 | 10 | 30.0 | 18.5 |

| 150 | 6" | 125 | 6000 | 10 | 48.7 | 33.8 |

| 200 | 8" | 125 | 6000 | 12 | 75.5 | 52.0 |

| 250 | 10" | 140 | 3000 | 12 | 98.5 | 62.5 |

| 300 | 12" | 150 | 3000 | 12 | 120.0 | 82.0 |

| 350 | 14" | 200 | 3000 | 12 | 157.0 | 84.0 |

| 400 | 16" | 200 | 1500 | 12 | 192.0 | 95.6 |

| 450 | 18" | 210 | 500 | 15 | 214.0 | 108.0 |

| 600 | 24" | 240 | 500 | 15 | 335.0 | 145.0 |

SPECIFICATIONS:

FAAB can supply with a complete range of the full piping system in SS 304 Lined Pipes & Fittings, SS 316 Lined Pipes & Fittings, and MS Lined Pipes & Fittings. We manufacture piping system with all wetted parts PTFE / PFA and steel external finish of stainless steel.

At FAAB we use basic raw materials from renowned all the world over suppliers like DuPont, USA, and GFL, India supported by the state of the art technological know-how and Thermoplastic Techniques like Paste Extrusion, Compression Moulding, and Injection Moulding along with a dedicated team of Engineers, Technicians, Computer-aided Designers, and others make it come alive as long-lasting corrosion-free systems.

Corrosion performance of the stainless steel is well known, hence spending 20 % to 25 % cost on painting lines can be saved besides the life of the systems is increased considerably if it is to be used for the longest time.

ADVANTAGES OF PTFE LINED PIPE & FITTINGS :

- Chemical inertness except for Fluorine and its compounds and highly Violent

- Reducing Agents.

- Low Co-efficient of friction.

- Little water absorption.

- Non-Toxic.

- Non-Inflammable.

- Excellent Weathering Resistance.

- Alternative to expensive alloys and exotic metals.

- Long service life, Maintenance-free, easy to install to ensure little or no

- equipment or plant downtimes means low operational costs.

- Exceptional corrosion resistance over a wide range of Ph and temperatures.

- Recommended for use in Multi-Component Mixture applications.

- Low risk of failure because of designs conforming to current International

- Standards to ensure hazard-free environment.

- No contamination of flow media.

QUALITY CONTROL FACILITIES AVAILABLE AT FAAB:

- Hydro-Testing facility at 20-28 kg/cm2.

- Spark Testing facility at 10KV -15 KV DC after lining.

- Hardness Tester for Moldings.

- Tensile Strength Testing Machine.

- Specific Gravity Testing Machine.